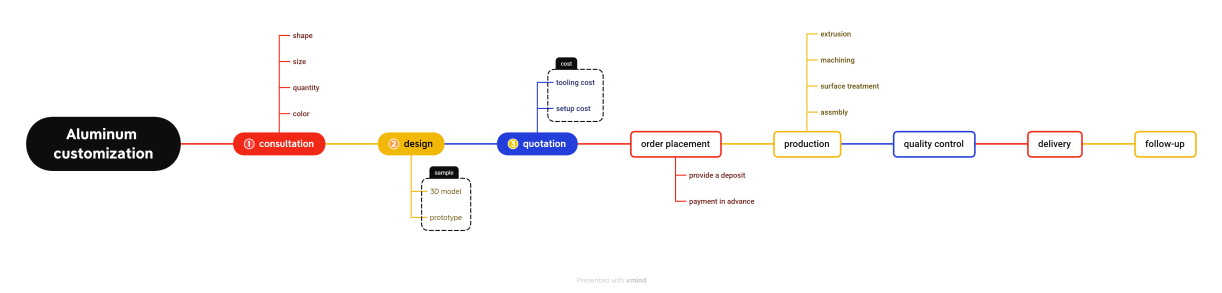

Consultation: The first step in the aluminum customization order process is to consult with us to discuss your specific needs and requirements. This may include the desired shape, size, quantity, and any special features or finishes.

Design: Once we have a clear understanding of your needs, we will work with you to design the aluminum product to your specifications. This may involve creating 3D models or prototypes to ensure that the product meets your requirements.

Quotation: After the design has been finalized, we will provide you with a quotation for the cost of the aluminum product, including any tooling or setup costs.

Order placement: If you are satisfied with the quotation, you can place an order for the aluminum product. This may involve signing a contract or purchase order and providing a deposit or payment in advance.

Production: we will then begin production of the aluminum product, using the design and specifications that were agreed upon. This may involve a range of processes, including extrusion, machining, surface treatment, and assembly.

Quality control: Throughout the production process, FM will conduct quality control checks to ensure that the aluminum product meets your specifications and standards.

Delivery: Once the aluminum product has been completed and passes quality control checks, it will be packaged and shipped to your location. FM will provide you with tracking information so that you can monitor the delivery status.

Follow-up: After you receive the aluminum product, FM will follow up with you to ensure that you are satisfied with the product and to address any concerns or issues that may arise.