FM Metal - Experienced Aluminum Manufacturer and Supplier

Aluminum coil is a metal product that is processed through

rolling, bending and angle processing by a casting and rolling machine before

flying shear.

The raw material of aluminum strip is pure aluminum or

aluminum alloy casting and rolling aluminum coil, hot rolled aluminum coil,

which is rolled into different thickness and width of thin aluminum coil by

cold rolling machine, and then longitudinally cut into different widths of

aluminum strip according to its use. Our company always has stock of aluminum coils/strips

of series 1060, 3003, 5052, 7075, etc.

Aluminum strip/coil has the advantages of light weight,

corrosion resistance, good conductivity, easy processing and forming. It is

widely used in construction, electronics, packaging, transportation and other

fields.

1. Lightweight and strong: Aluminum is a lightweight but strong metal, making it ideal for use in various applications.

2. Corrosion-resistant: Aluminum has excellent corrosion resistance, making it suitable for use in harsh environments.

3. Ductile: Aluminum can be easily formed into different shapes without cracking or breaking.

4. Good conductivity: Aluminum has good electrical and thermal conductivity.

1. Energy-efficient: Aluminum coils are commonly used in HVAC systems due to their energy efficiency.

2. Cost-effective: Aluminum is a relatively low-cost material compared to other metals such as copper or stainless steel.

3. Recyclable: Aluminum is 100% recyclable and can be reused indefinitely without losing its properties.

4. Versatile: Aluminum coils can be used in various applications, including construction, transportation, packaging, and electronics.

Types | 1100 1200 1050 1060 1070 3003 3004 5052 5083 5754 6061 6063 7075 8011 8A06 491 |

||

|

Width

|

600-2600 mm or Customized width

|

||

|

Thickness

|

0.2-3 mm

|

||

|

Processing

|

Punching, Brushed, Polishing, Anodizing, Embossing, and Color Coeated, F-C paint

|

||

Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194 | ||

MOQ | 5 Tons | ||

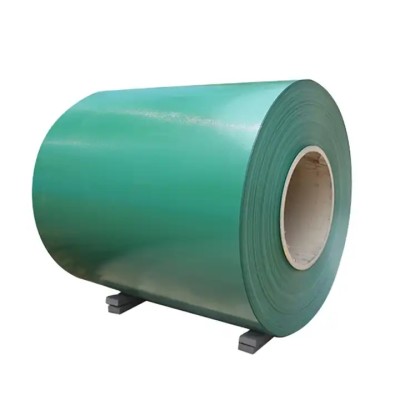

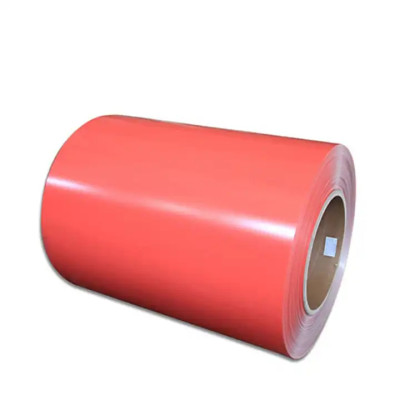

Coating treatment can improve the corrosion resistance, wear resistance, weather resistance and surface hardness of aluminum coils. Here are several frequently applied examples of the appearance of aluminum coils with coating processing.

Aluminum coils can be coated in different colors to meet

various appearance requirements. As shown in the image below, aluminum coils

can be sprayed with a wide range of colors.

Aluminum coils can be coated with anti-corrosion coatings to

effectively prolong their service life. As shown in the image below, such

coated aluminum coils are often used in the manufacture of various industrial

equipment and building materials.

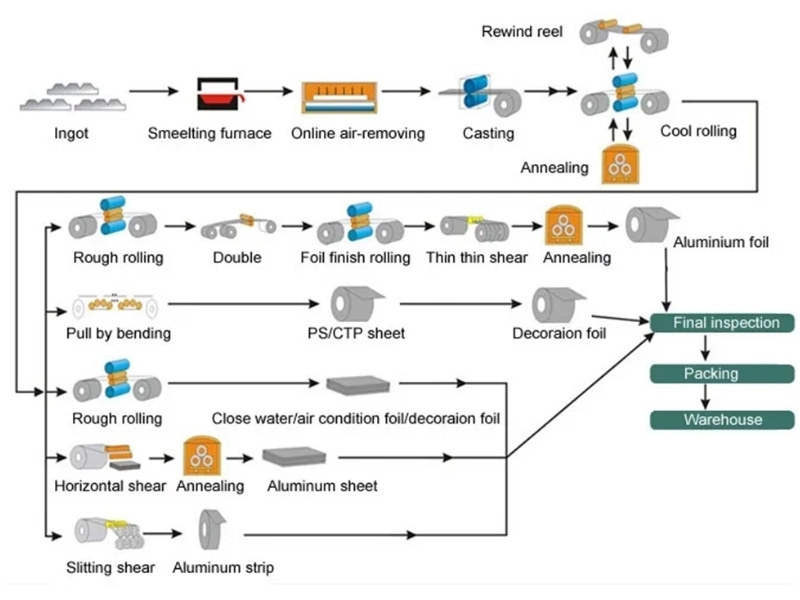

Aluminum coils can be fabricated into products of various shapes and sizes. One such process is slitting, which involves cutting the aluminum coil into plates or sheets of desired length and width. Another method is laser cutting, where a laser cutting machine is used to precisely cut the aluminum coil into different shapes and sizes, including aluminum tubes and other intricate designs.

- Name:

- FM Metal

- Tel:

86-18924839433

86-13360350815

86-13652267423

- Email:

- FMAlumetal@gmail.com

- WhatsApp:

- https://wa.me/8618924839433

- Skype:

- Skype:008613360350815

- Address:

- Building 1st, Jinchang International Metal Trading Market, Chencun Town, Shunde District, Foshan City, China